Is Schedule 40 Pipe Suitable For Structural Applications?

Investigating the Significance of SCH 40 in Steel Construction

Schedule 40 pipe is generally accepted as a frequently used and highly adaptable form of carbon steel pipe in the steel sector. However, a question emerges among engineers, purchasers, and builders: Is Schedule 40 pipe suitable for structural purposes?

This article will explore the application of Schedule 40 and consider its importance in structural contexts.

Understanding what is “Schedule 40”

The designation Schedule 40 does not indicate a material grade or strength specification—it refers to the wall thickness of a pipe which follows ASME/ASTM dimensional guidelines.

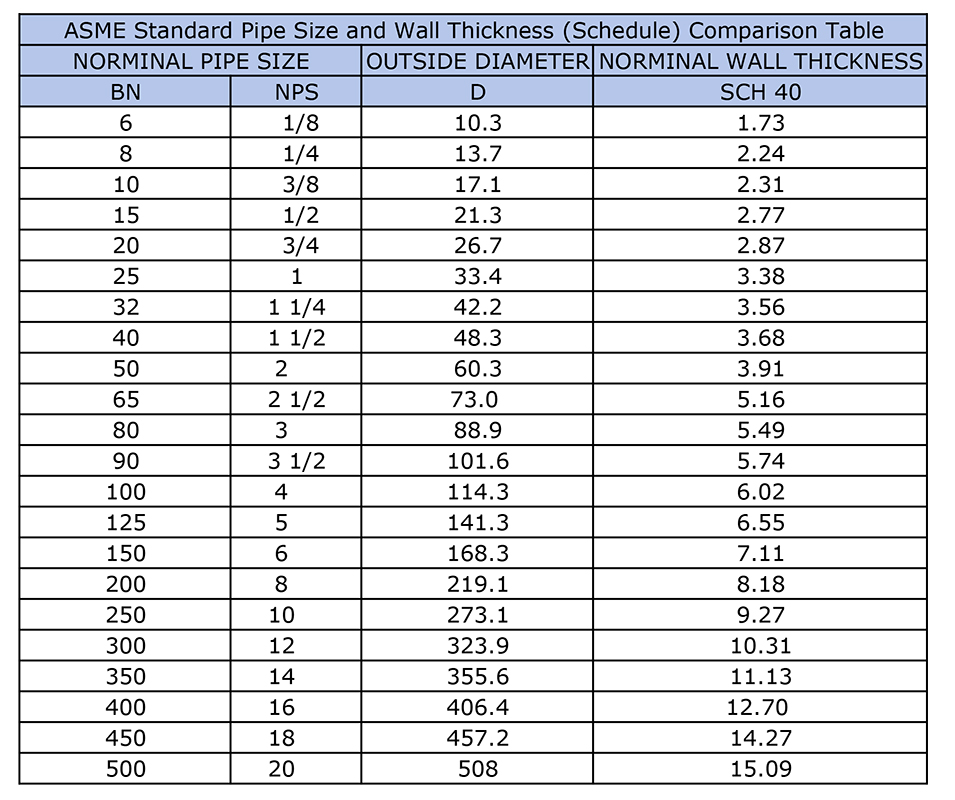

From the table we can see, a 2-inch Schedule 40 pipe features a wall thickness of 3.91 mm, whereas a 8-inch pipe measures 8.18 mm. These dimensions are standardized by ASME B36.10M, mainly intended for pressure piping in fluid conveyance systems.

Engineered for Pressure, Not Structural Loads

Schedule 40 pipes are typically produced according to standards like ASTM A53, ASTM A106, or API 5L. These specifications emphasize pressure containment, weldability, and corrosion resistance, rather than structural capacity.

This implies that the pipes are designed to withstand internal pressure, not necessarily external forces such as bending or compression in structural frameworks.

Is Structural Use Possible?

Yes—though with certain restrictions.

Schedule 40 pipe can be employed in lightweight or non-critical structural projects, particularly in applications like:

- Guardrails, fencing, and handrails

- Support frames and shelving units

- Signage posts and small truss assemblies

In these scenarios, Schedule 40 is an economical option due to its sufficient strength for non-critical applications and its widespread availability.

Nonetheless, when we select products for load-bearing structures or components within certified engineering designs and structural, grade steel pipe such as ASTM A500 or ASTM A252 should be selected instead. Because these are specifically engineered for structural soundness and undergo mechanical performance testing.

Comparing Schedule 40 and ASTM A500 Structural Tubing

As the table shows, when there is a need for strength, uniform tolerance, and consistent performance under load, the better choice is ASTM A500.

Final Thoughts

Schedule 40 pipe continues to be one of the most widely used and cost-effective steel pipe varieties available. It excels in fluid systems, general fabrication, and light structural tasks.

However, it is essential to choose certified structural steel pipe or tubing (such as ASTM A500 or A252) for projects requiring engineered structural dependability.

This ensures not only adherence to design codes, but also the long-term safety and performance of your project.

Tianjin Yuantai Derun Steel Pipe Group is a trusted supplier of Schedule 40 steel pipes and ASTM A500 structural tubes, offering comprehensive products and mill test certification for export customers worldwide.

For more information or questions, please reach out—our technical team is available to assist in choosing the appropriate steel for your requirements.