Understanding R Angle in Square and Rectangular Steel Tubes

Square and rectangular hollow sections may look simple, but many technical details affect their strength and performance. One of the most overlooked yet critical features is the R angle, also known as the corner radius. It plays a major role in forming quality, weld behavior, load performance, coating adhesion, and visual appearance.

This article explains what R angle is, how major standards specify it , how it is measured, and what buyers should pay attention to when selecting tubes.

What is R Angle?

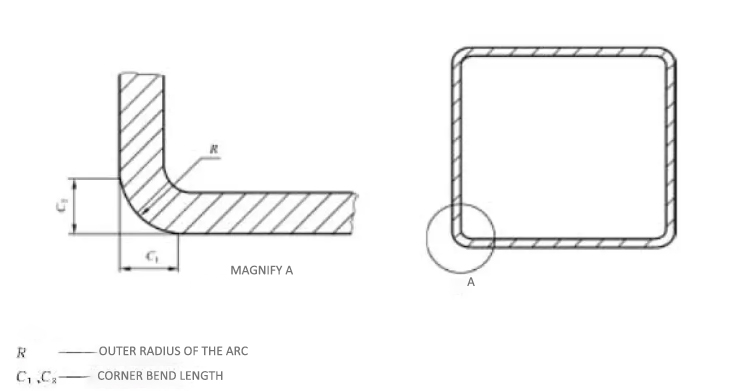

The R angle refers to the radius of the outer corner arc of a square or rectangular steel pipe.

Instead of a sharp 90-degree edge, the corner is formed into a rounded curve during shaping or extrusion.

It affects:

Structural performance

Weldability

Aesthetics

Coating thickness distribution

Connection fitting and tolerance control

Although it seems minor, improper corner radius can directly influence engineering results.

R Angle Requirements Under Common Industrial Standards

Different regions and standards define R angle tolerance differently.

Here is a simplified reference:

◎ Chinese Standard (GB/T 3094, GB/T 6728)

Corner radius typically ranges between 1.5 × wall thickness to 3 × wall thickness

Some applications allow minimum R ≥ 2mm

◎ European Standard EN10210 (Hot Formed)

Higher wall thickness tolerance and larger radius

Normal R angle ≈ 2 × wall thickness, but may reach 2.5 × or 3 × for large sections

◎ EN10219 (Cold Formed)

Smaller radius relative to EN10210

Typical R ≥ 1.5 × wall thickness

◎ British Standard BS EN10219 / BS 4360

Aligns closely with EN10219 requirements

Focuses more on corner shape consistency and deviation limits

◎ Japanese Standard JIS G3466

Defines R angle as around 1.2 × to 2.0 × wall thickness

Known for stricter dimensional control

✔ In actual applications, corner radius is not fixed; it varies based on the forming technology, tooling dimensions, and intended use.

✔ Manufacuturing tolerances often vary between different suppliers.

Formula Reference and Measurement Method

R Angle Estimation Formula (Industry Rule of Thumb):

R ≈ 1.5–3.0 × wall thickness (t)

Example:

If wall thickness is 5mm → R angle ≈ 7.5mm–15mm

Field Measurement Method

R angle can be checked by:

✔ Radius gauge tools

✔ Measuring circle templates

✔ Profile coordinate measuring machine

Steps:

Place gauge or template along the tube corner

Match the fitting arc

Read value or record fit tolerance

Compare with standard or order requirement

Large projects sometimes use 3D scanning or CMM to ensure geometric accuracy.

Why Does R Angle Matter?

The corner radius affects:

✔ Strength — reduces stress concentration

✔ Coating — ensures galvanizing coverage at edges

✔ Welding — improves fusion quality

✔ Aesthetics — smoother appearance

✔ Assembly — affects slot fit and connector size

For thick-walled square tubes or structural applications, incorrect R angle can result in gaps, welding problems, or hidden fatigue risks.

What to Check When Purchasing Steel with R Angle Requirements

Buyers should evaluate:

① Confirm Standard Compliance

Ask supplier which forming process and standard they follow

(EN10210, EN10219, GB, JIS, BS have different corner shapes).

② Ensure Radius Meets Application Needs

Large R → smoother, stronger, easier coating

Small R → sharper edges, tighter fit with connectors

③ Check Wall Thickness and R Matching

Corner radius is proportional to wall thickness—too small radius for thick tubes often indicates improper forming.

④ Verify Real Measurement

Request:

Radius gauge test data

End-cut photos

Dimensional inspection sheet

⑤ Pay Attention to Post-Processing

Hot dip galvanizing, punching, or machining requires suitable corner radius for coating flow and structural stability.

Conclusion

R angle is not a cosmetic detail.

It influences forming quality, load performance, service life, and installation precision.

Understanding how different standards define corner radius—and knowing how to measure and evaluate it—helps ensure proper material selection and reliable engineering results.